Products

- All

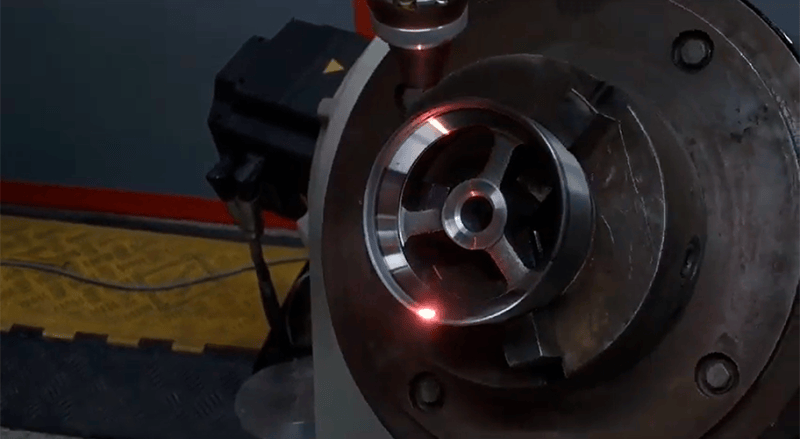

- Hardening

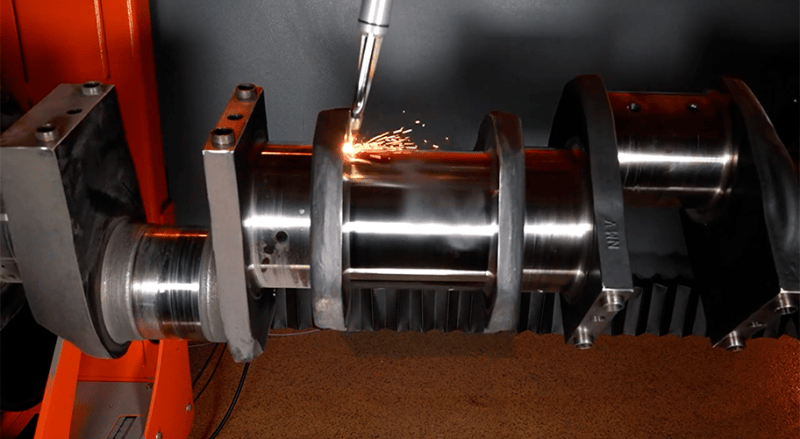

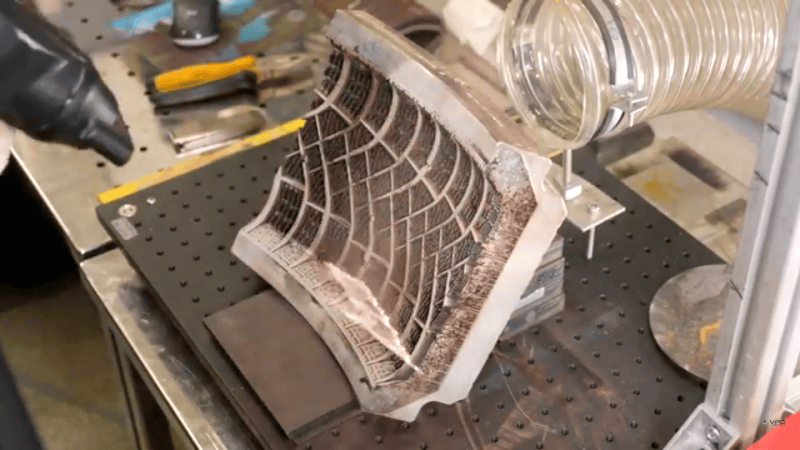

- Powder cladding

- Wire cladding

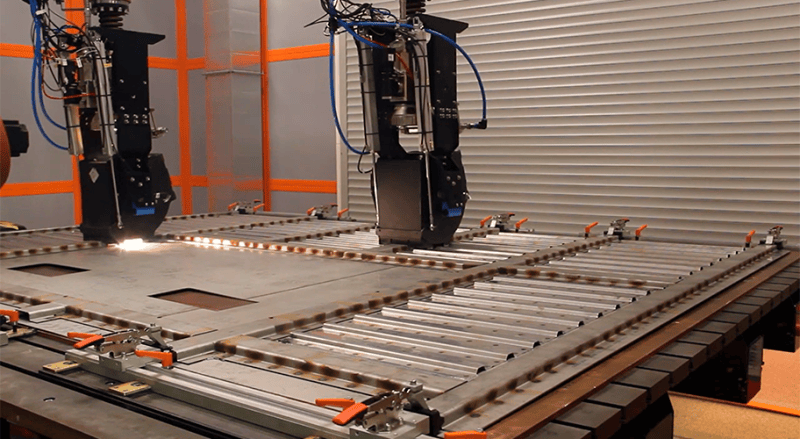

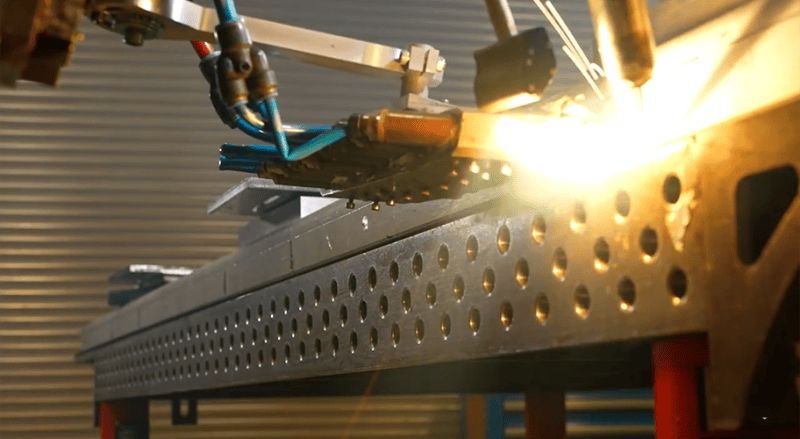

- Welding

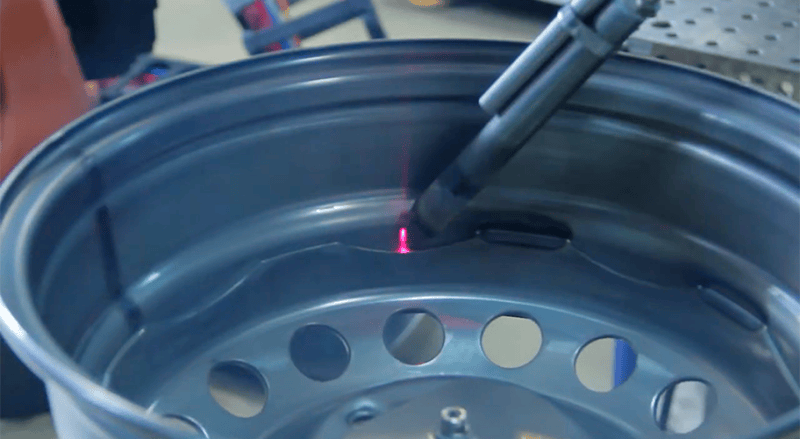

- Pre and post weld cleaning

- Surface cleaning

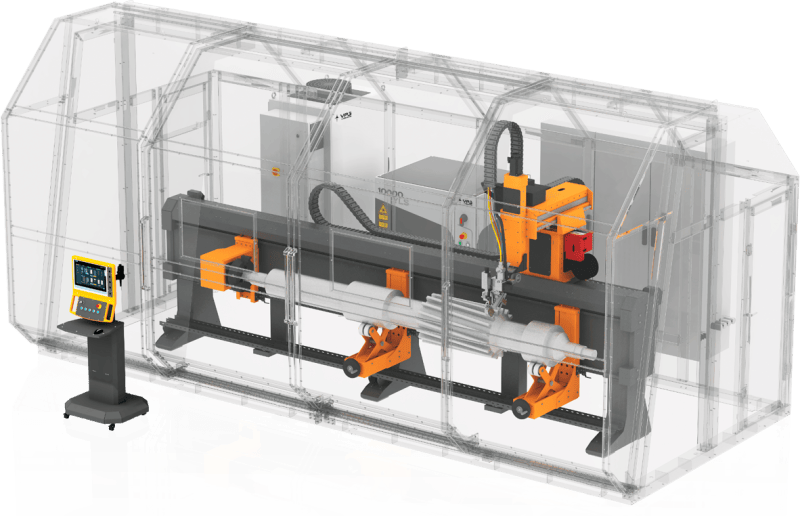

- 2D/3D metal cutting

- Metal cutting

- 3D printing (SLM/SLS)

Key advantages

- Laser cladding and hardening substantially extend component life in rail and transport, cutting replacement spend by roughly 5–8×

- Minimal heat-affected zone and near-zero distortion preserve tight tolerances and geometric stability of parts

- Laser coatings and hardening reach hardness levels up to ~850 HV, delivering high wear resistance under heavy mechanical and thermal load

- Localised laser input lowers energy usage and eliminates waste; consumable utilisation reaches ~90–100%

- Laser cleaning is non-abrasive and eco-friendly — removing rust, paint and oils to Sa2–Sa3 surface quality without harming the substrate

- Digitally controlled laser processing ensures repeatable results with low operator error — ideal for consistent quality in high-volume repairs

Discover new opportunities in the laser industry

We focus on continuous technological development and strive to exceed our customers’ expectations