Products

Applications

Key advantages

- Enables the use of a wide range of alloy and carbide powders for functional and wear-resistant coatings

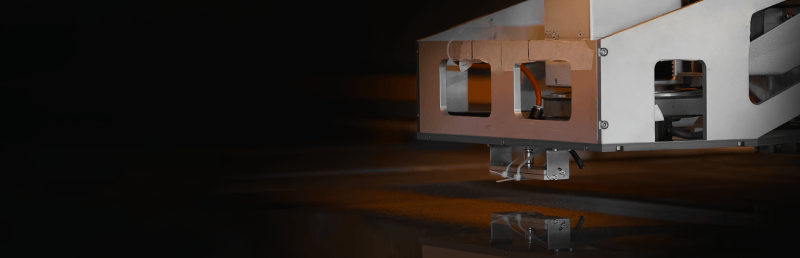

- Provides precise control over layer thickness and surface geometry, ideal for fine restorations and coatings

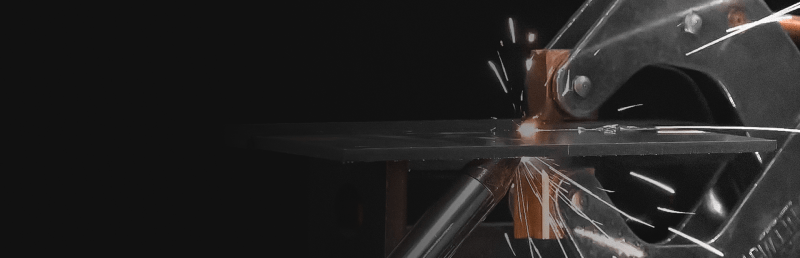

- Produces dense, high-hardness coatings (up to 1000 HV) with excellent wear and corrosion resistance

- Minimizes thermal distortion due to localized energy input and rapid cooling rates

- Enables precise restoration of complex or high-value components like bearings, rings, and blades

- Delivers fine-grained microstructures with strong metallurgical bonding to the substrate

Other Applications

Discover new opportunities in the laser industry

We focus on continuous technological development and strive to exceed our customers’ expectations