Products

Applications

Key advantages

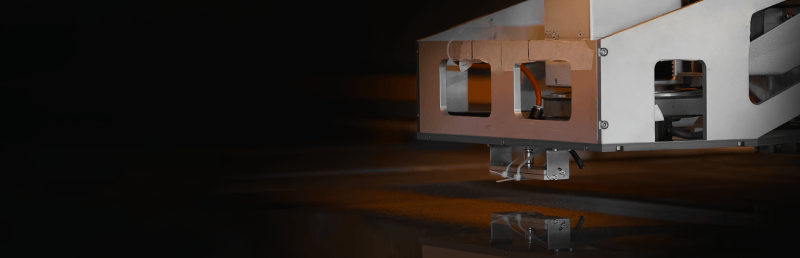

- Tempering-resistant marking enables identification and branding even after heat treatment processes

- Surface and in-depth marking capabilities allow flexible application depending on design or functional requirements

- Non-contact, high-precision process ensures clean, damage-free marking without affecting glass transparency or integrity

- Integrated marking during cutting cycles streamlines production and reduces handling time

- Durable, wash-proof markings withstand cleaning, environmental exposure, and mechanical stress

- Compatible with large-format sheets and complex geometries, supporting architectural and industrial-scale applications

Other Applications

Discover new opportunities in the laser industry

We focus on continuous technological development and strive to exceed our customers’ expectations