Products

Applications

Key advantages

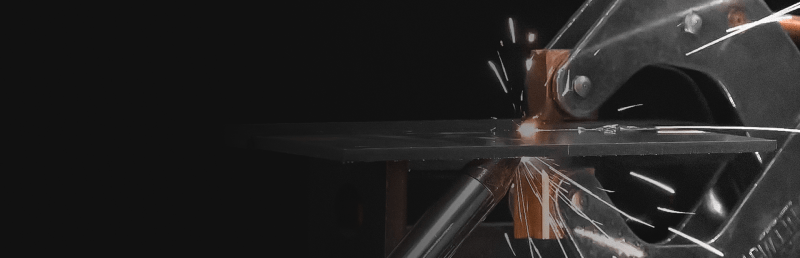

- Ensures high-precision, burr-free edges on laminated and monolithic glass, eliminating the need for post-cutting grinding or polishing

- Enables accurate, CAD-based processing of complex straight and curved shapes on laminated and float glass, with high contour precision and optimized nesting

- Contactless laser processing prevents microcracks, chips, and deformation, preserving edge integrity and structural performance

- Provides up to 4× faster throughput than traditional methods, significantly boosting productivity on large-format glass sheets (3210×6000 mm and above)

- Optimized nesting with thin lines and minimal trimcut reduces material waste by up to 75% compared to conventional methods

- Monolithic glass can be tempered immediately after laser cutting, eliminating edge seaming and speeding up architectural glass processing

- Offers environmental efficiency by reducing water use, abrasives, sludge generation, and energy consumption compared to traditional methods

Other Applications

Discover new opportunities in the laser industry

We focus on continuous technological development and strive to exceed our customers’ expectations