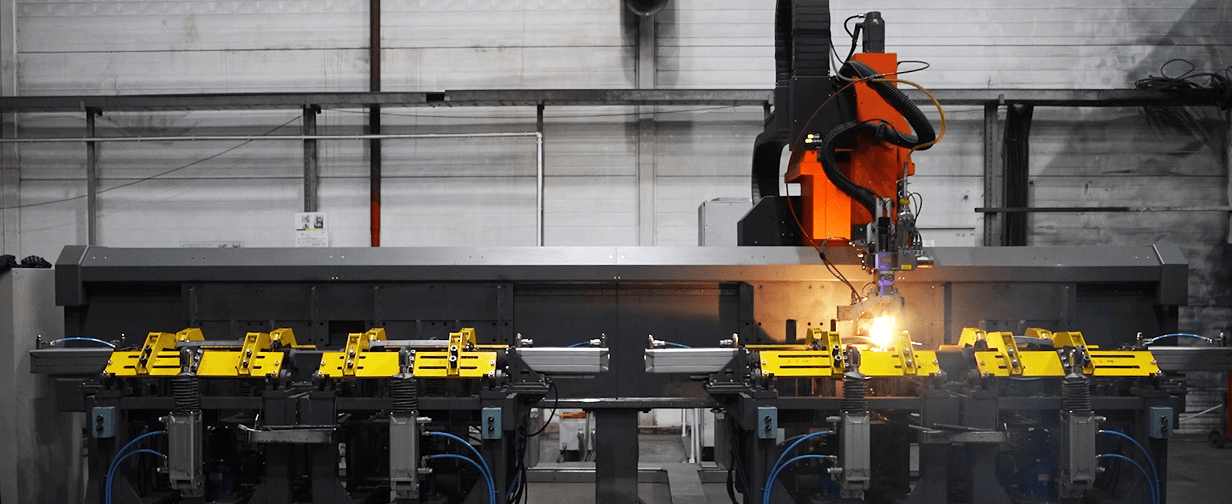

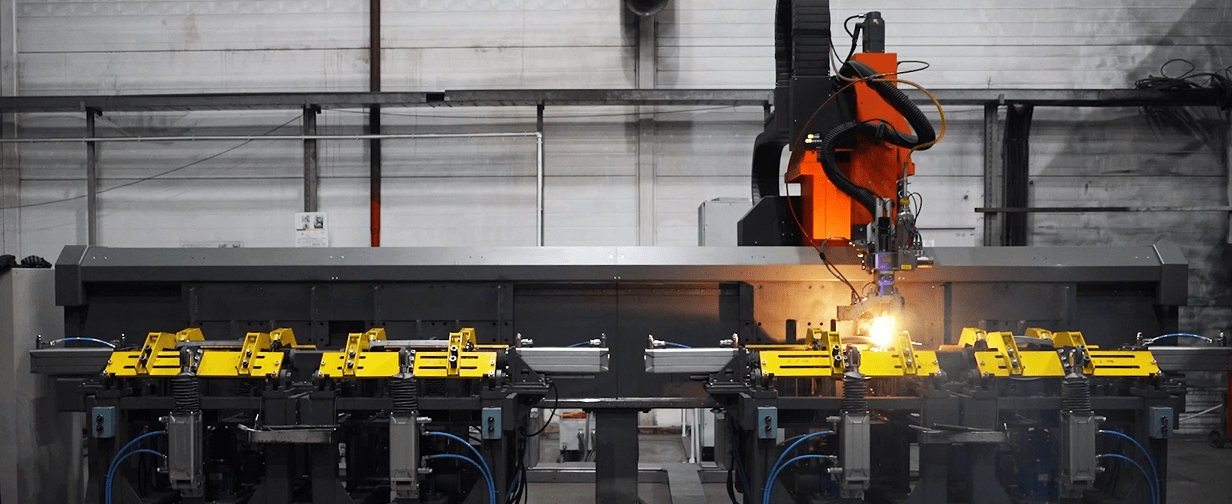

Product overview

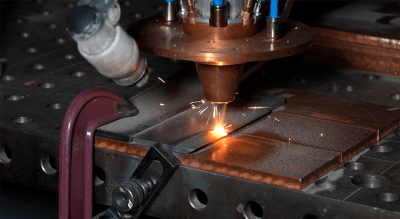

- 1–10m/minProcessing speed in laser welding

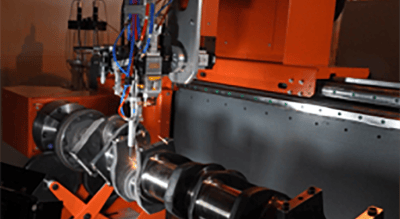

- 2xSurface hardness increases with uniform structure. Layer depth: 0.5–1.8 mm in laser hardening

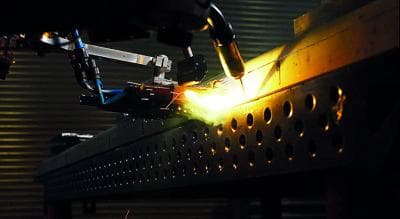

- 100%Material utilization in wire cladding. Up to 90% efficiency in powder cladding

Applications

Key advantages

Single-pass weld finish — no secondary machining required, saving time and lowering cost

Heats only the wear-prone zones, minimising thermal load on the remaining part

Laser thermal hardening cuts deformation by up to 10× versus conventional techniques

Rapid heat–cool cycles refine grain structure, improving material properties

In-house software enables full automation and seamless laser-process integration, with intuitive operation, flexible customisation and reliability tuned to specific production needs

Quickly reconfigure for new product variants, ensuring smooth changeovers and higher productivity

Cladding delivers clean separation with very low dilution between substrate and build-up layers

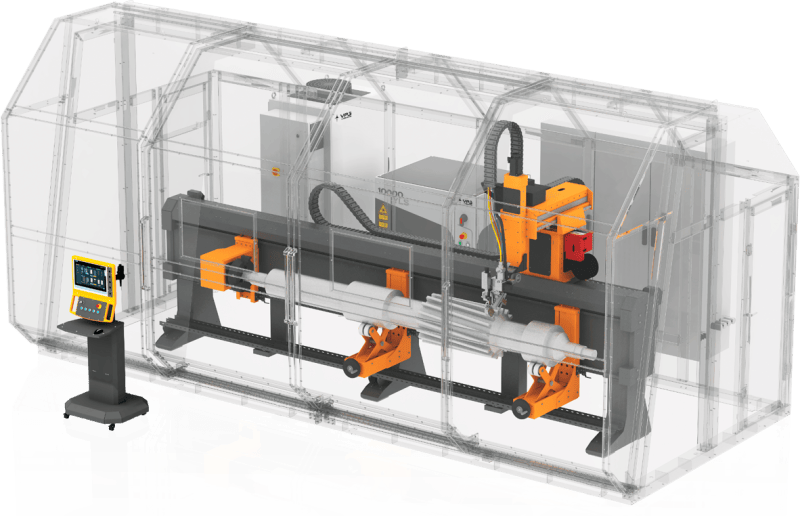

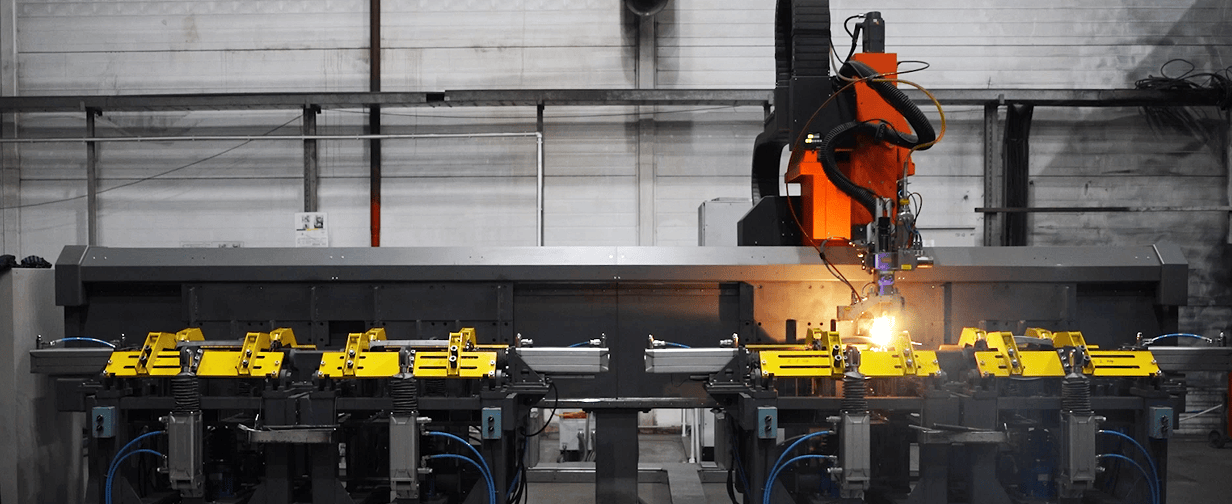

A modular coordinate system with interchangeable attachments allows machine layouts tailored to part geometry and throughput — boosting flexibility across applications

Maintenance-free, high-efficiency VPG LaserOne fibre laser reduces scheduled service, downtime and OPEX while ensuring long-term reliability and strong ROI

Specifications

Technology

Discover new opportunities in the laser industry

We focus on continuous technological development and strive to exceed our customers’ expectations