Products

- All

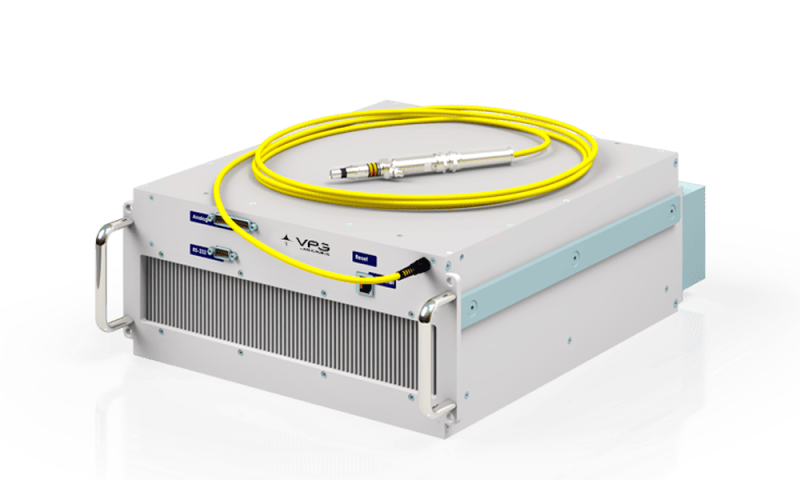

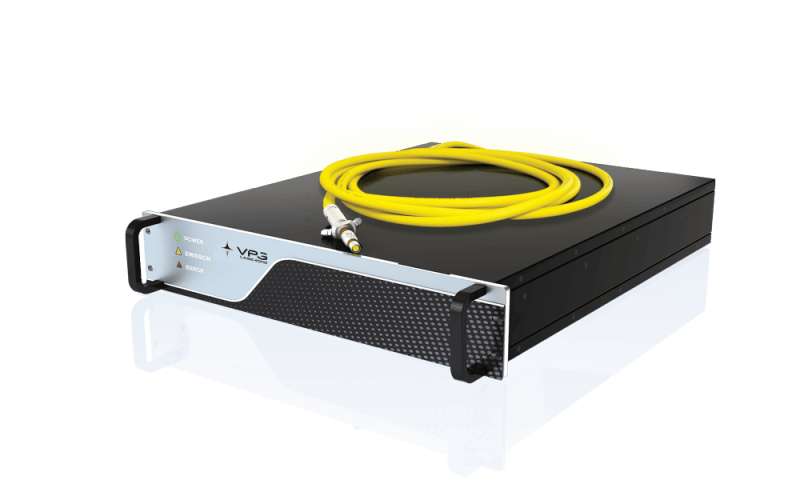

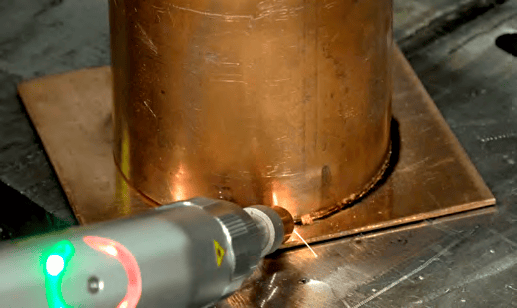

- Welding

- Pre and post weld cleaning

- Surface cleaning

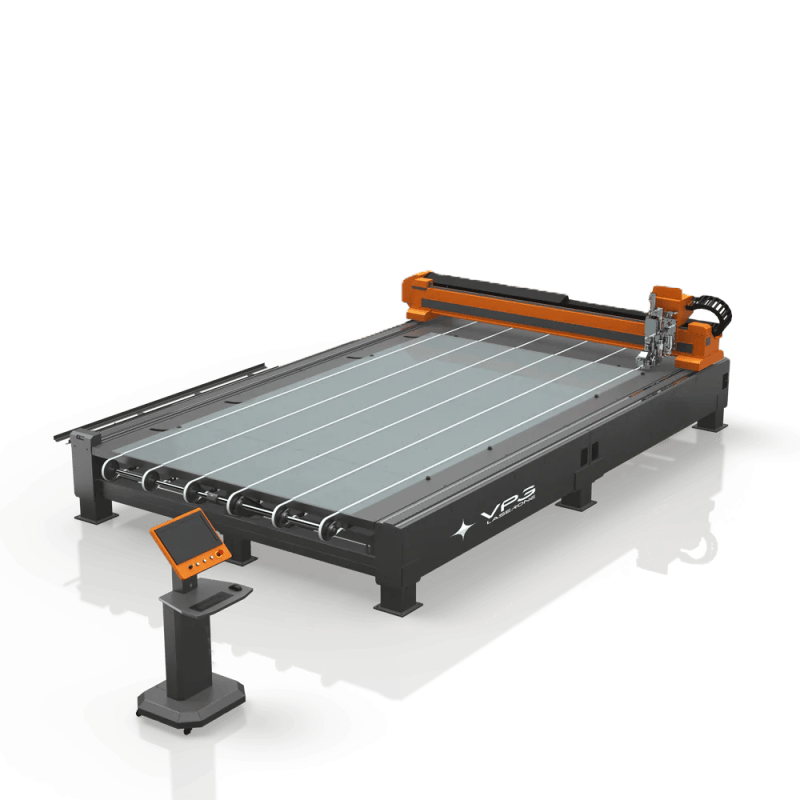

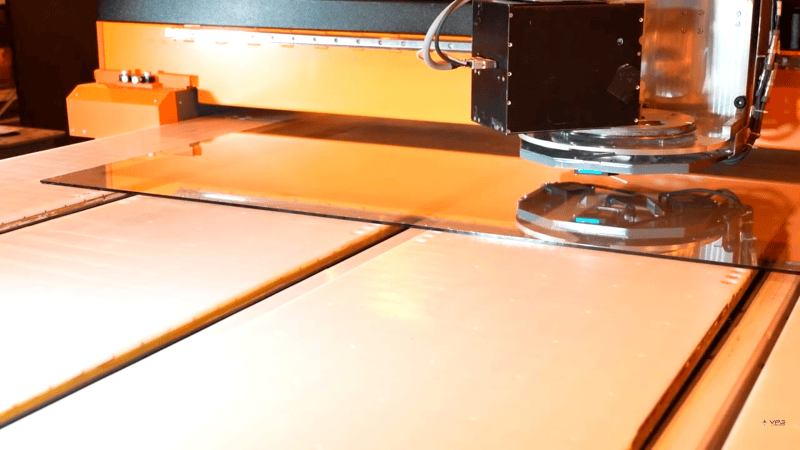

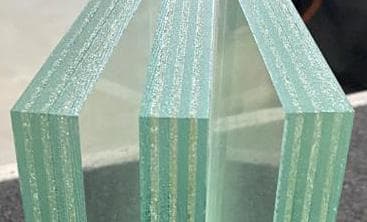

- Glass cutting

- Glass decoating

- Glass marking

- 2D/3D metal cutting

- Metal cutting

Key advantages

- High-strength welding with no distortion, automation-ready, and minimal post-weld clean-up

- Eco-friendly, non-abrasive surface cleaning — safe, consumable-free and suited to on-site use

- Precision glass cutting without chips or cracks, enabling complex geometries with no secondary finishing

- Decoating preserves transparency and mechanical integrity during edge-coat removal — ideal for architectural, structural and functional coatings

- Integrated processing of jumbo-sized glass — coat removal, layout and marking in a single cycle — streamlines flow and sharply reduces takt time

- Custom glass painting from design drawings — suited to architectural detailing, decorative work and bird-safety patterns

Discover new opportunities in the laser industry

We focus on continuous technological development and strive to exceed our customers’ expectations