Product overview

- up to 60kWOutput power

- >45%Wall-plug efficiency

- 36monthStandard warranty

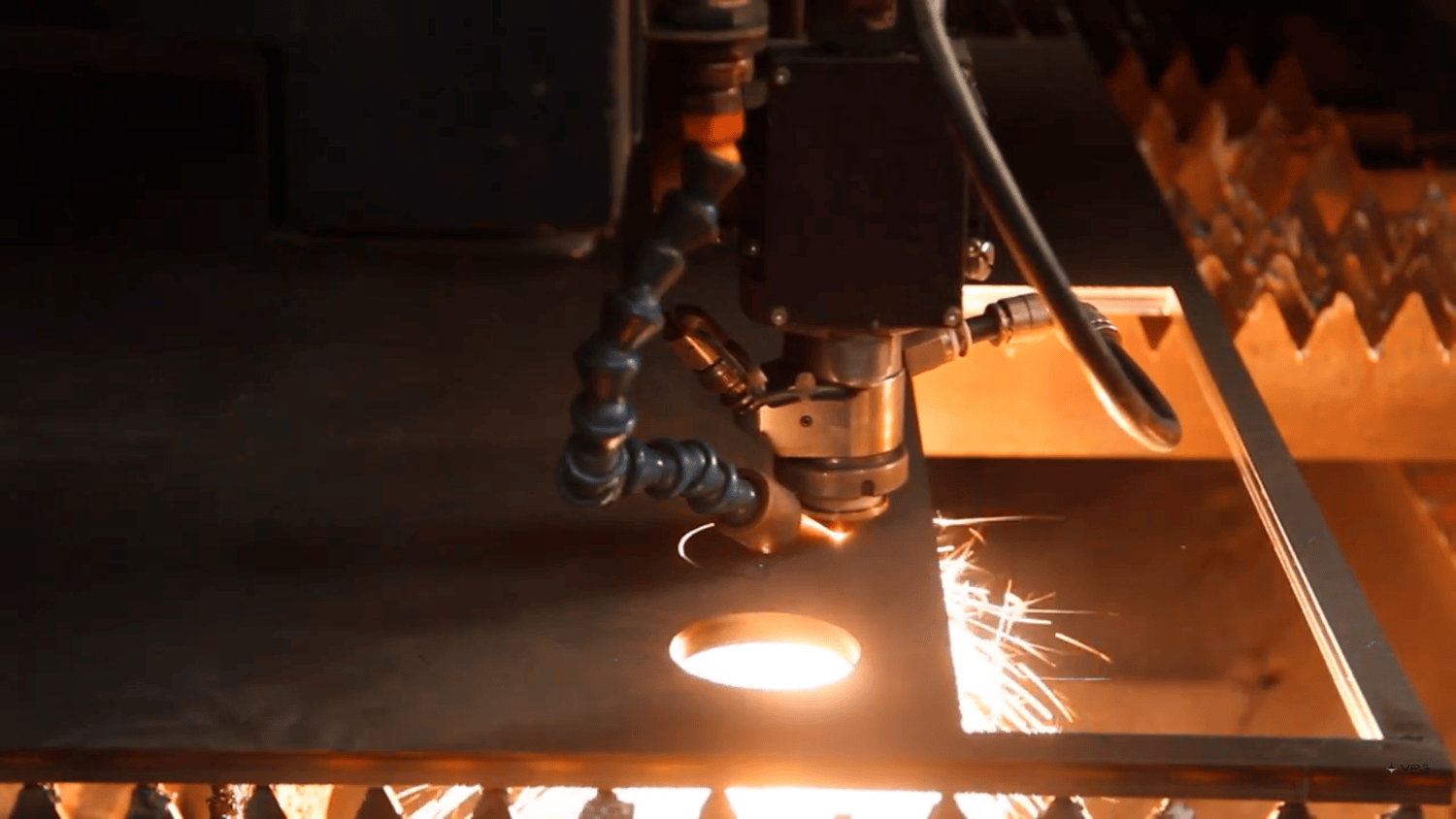

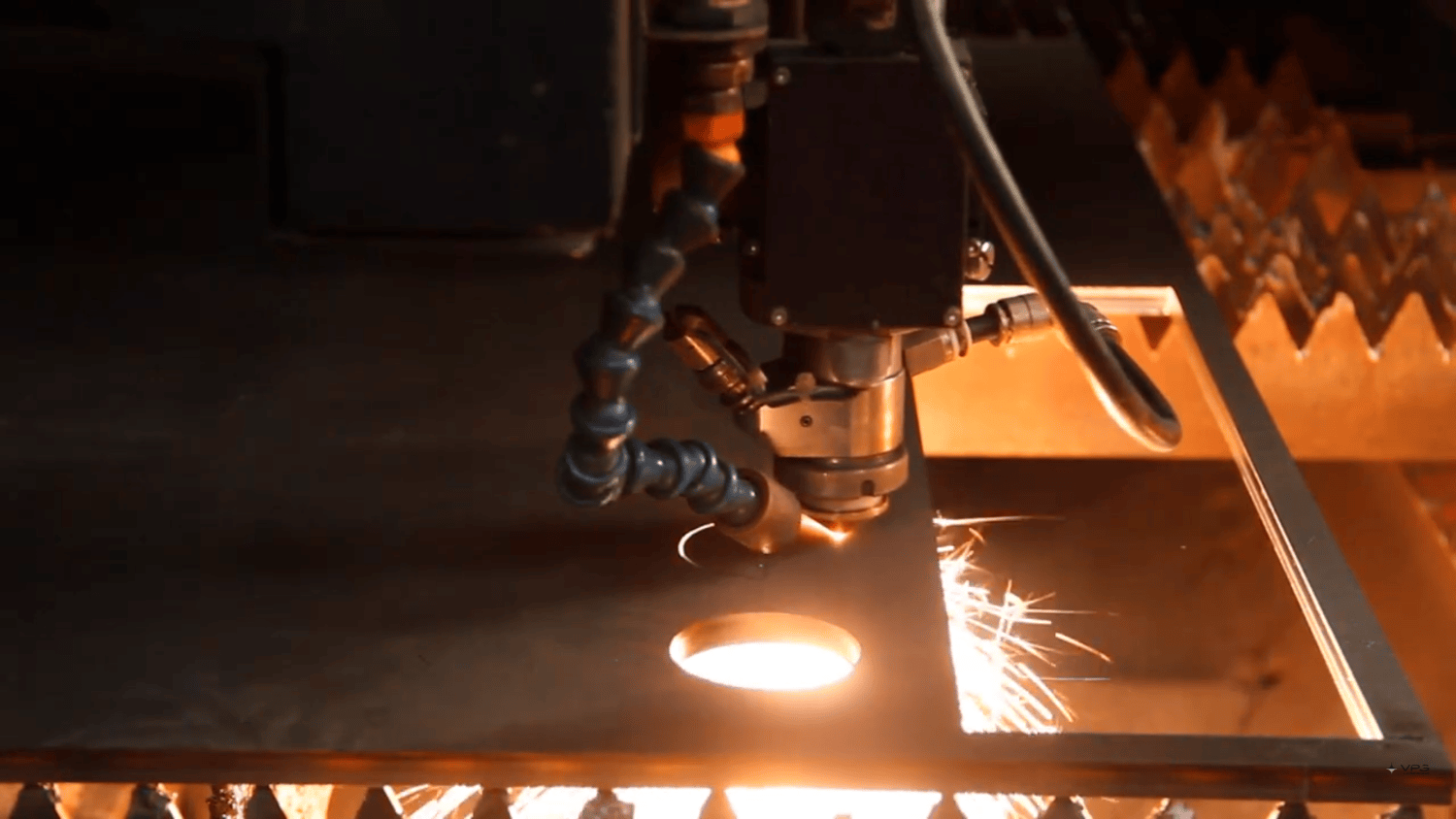

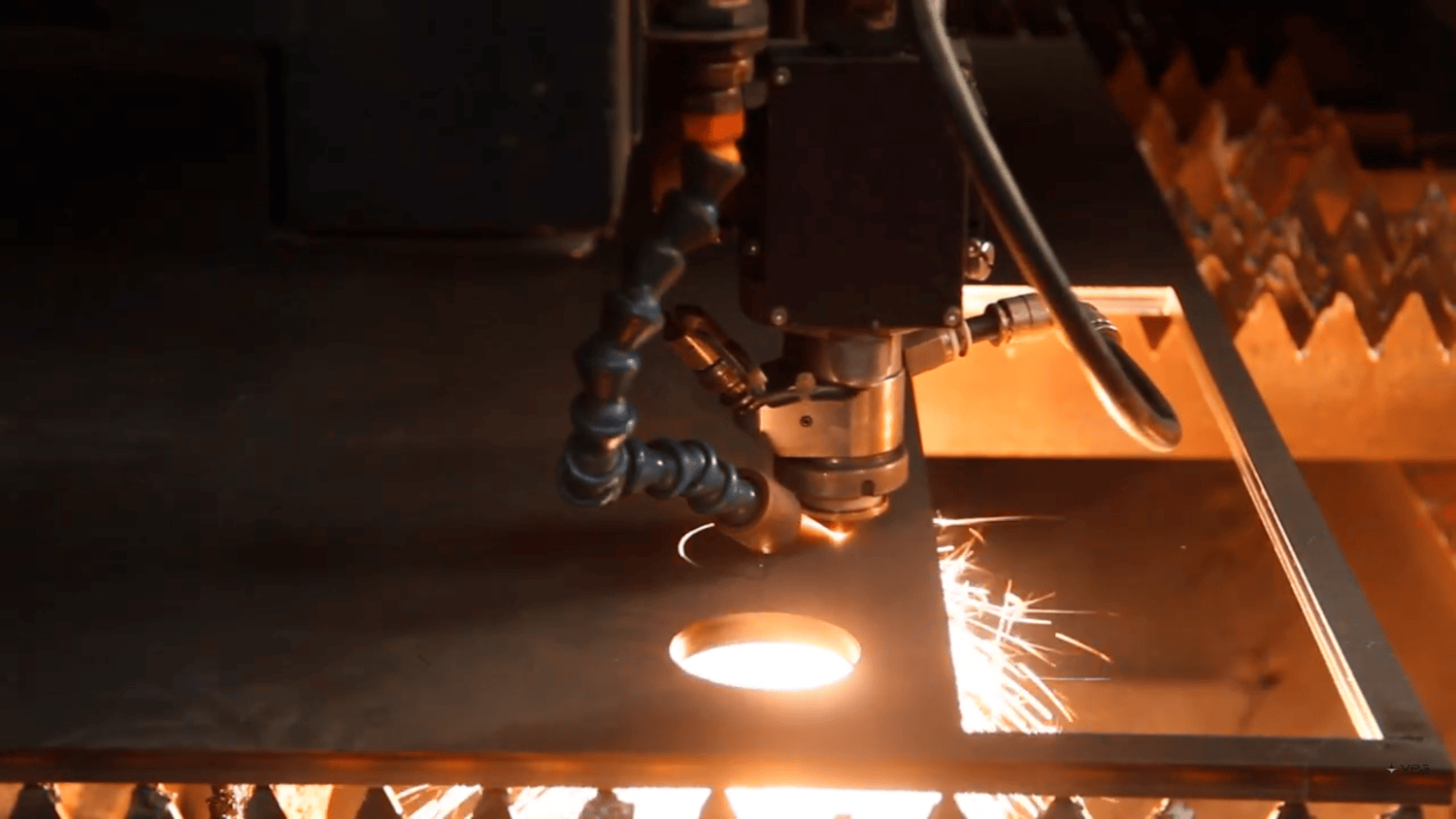

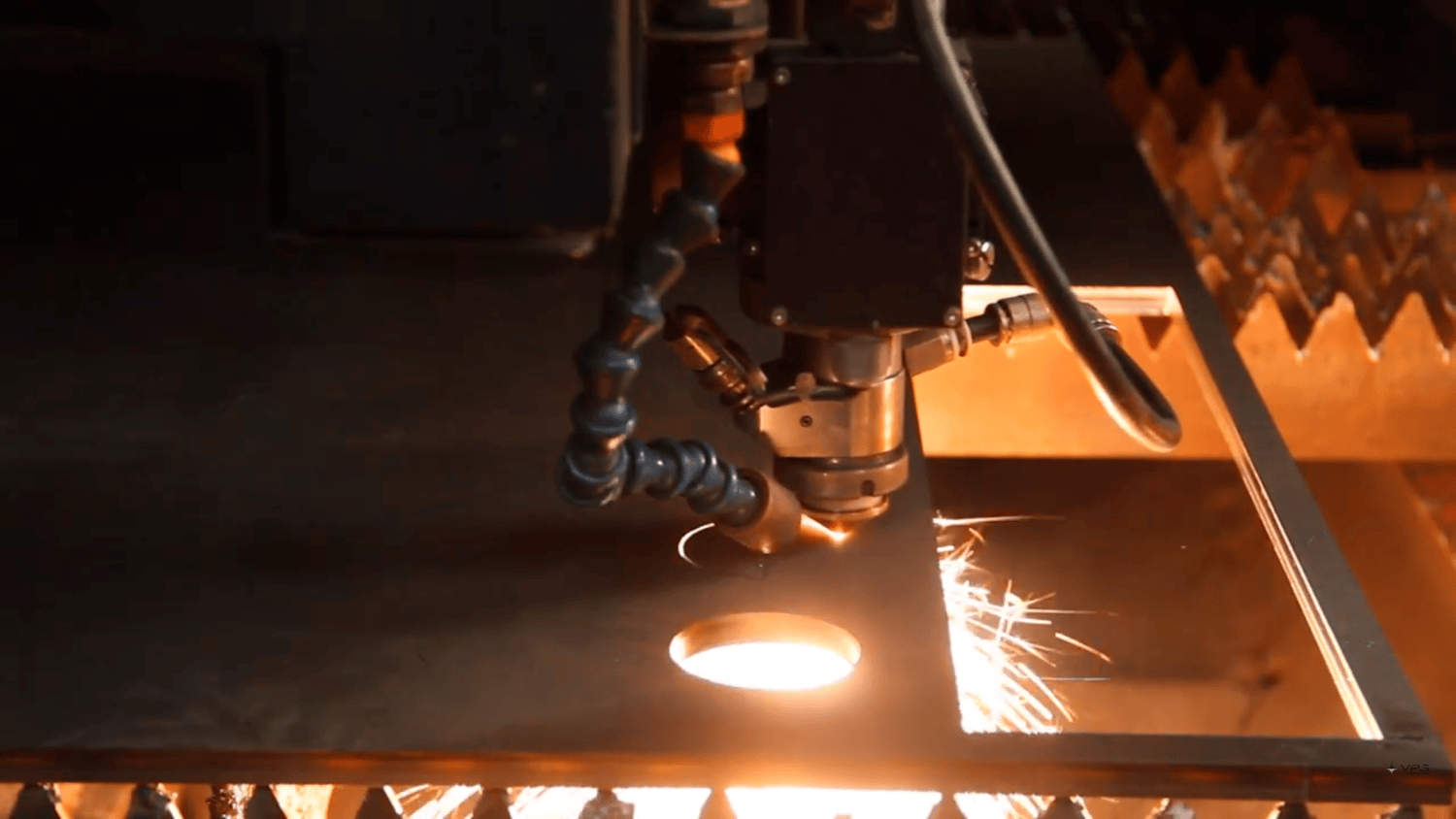

Applications

Key features and advantages

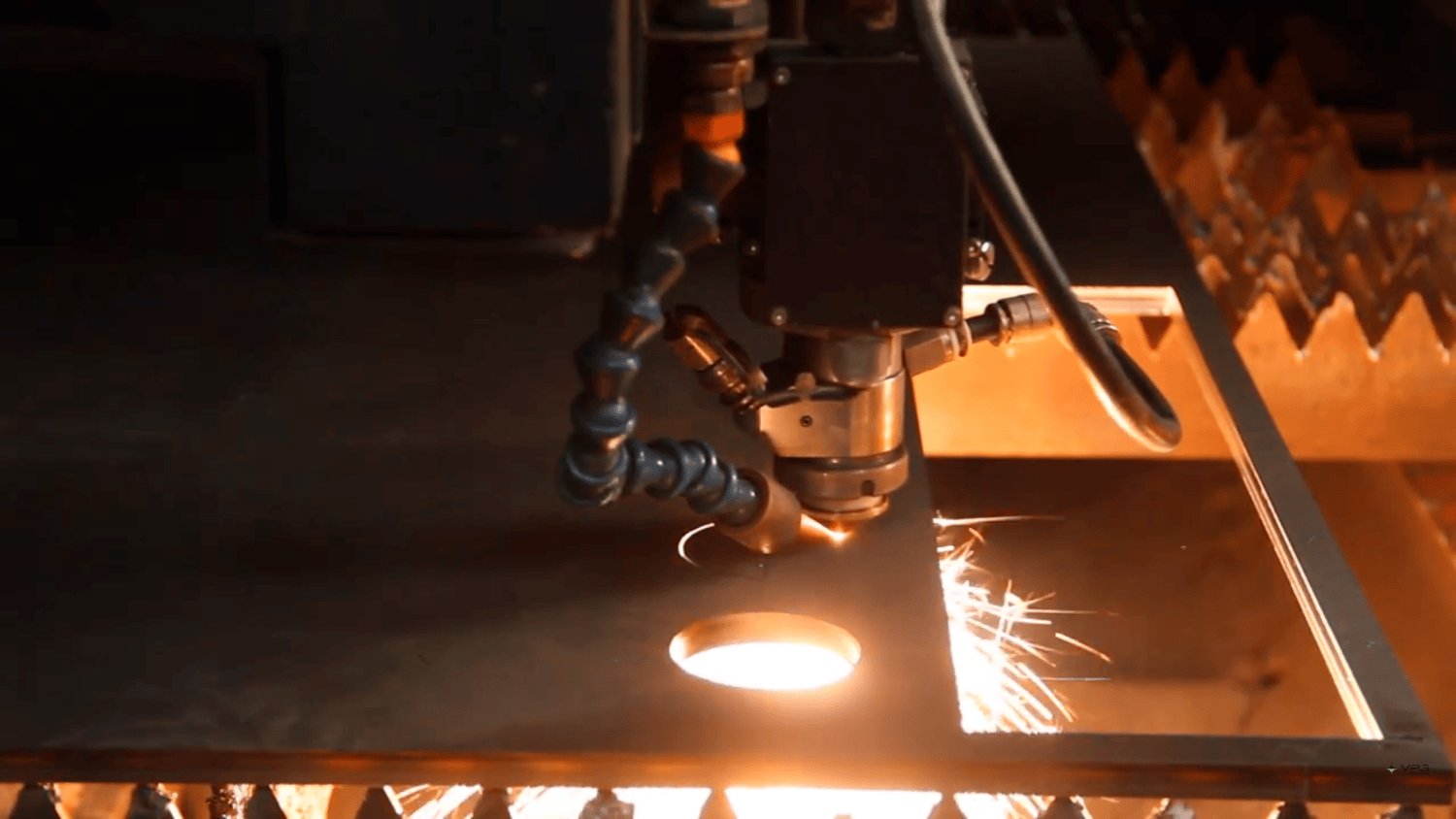

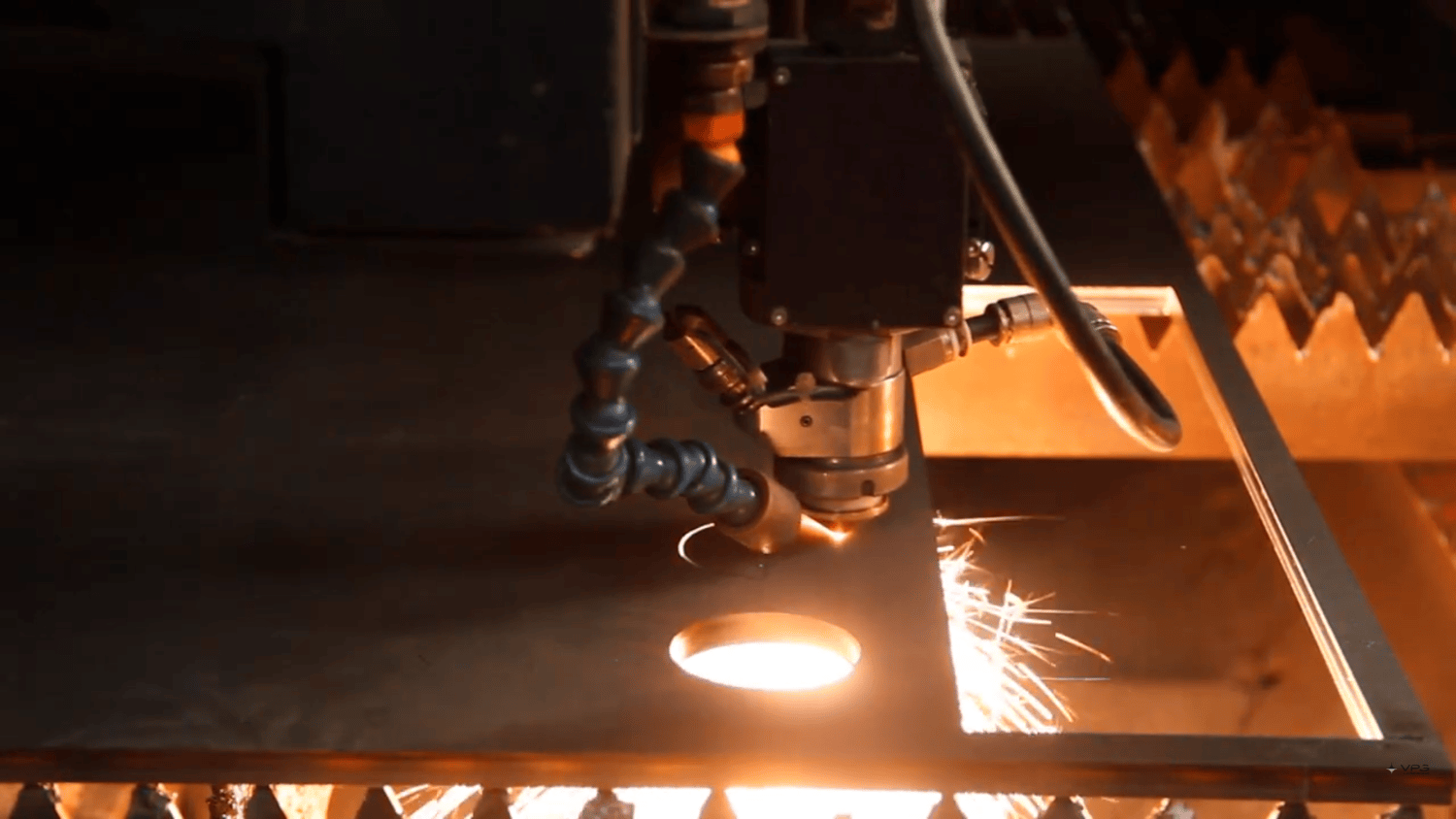

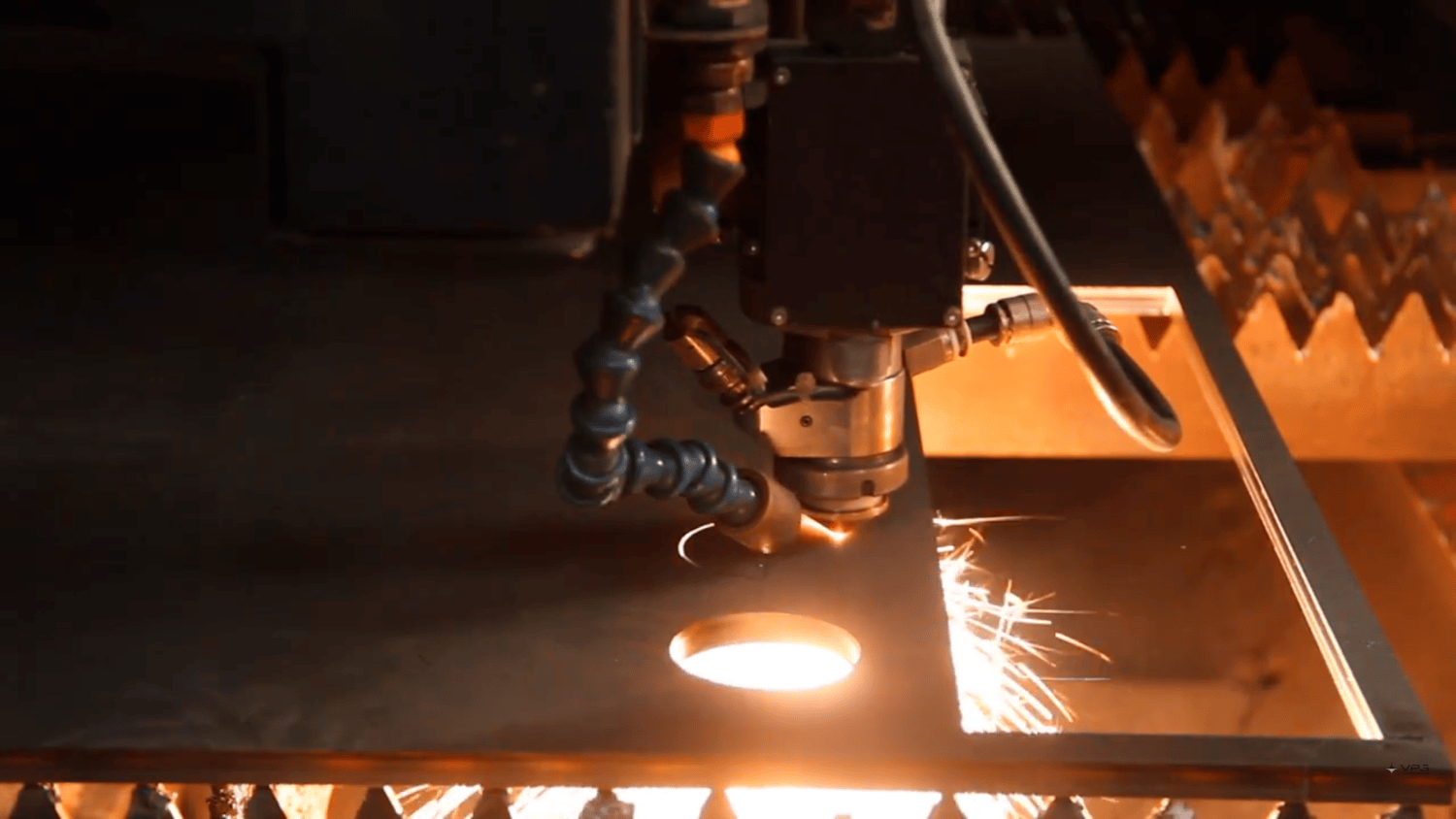

Produces a tightly focused spot with high energy density, enabling precise cuts, narrow kerfs and excellent processing accuracy.

Selectable fibre-core diameters (100–600 µm) let you optimize beam delivery for the task — from fine micro-work to high-power welding.

Optional industrial buses — EtherCAT, ProfiNet and others — enable smooth integration into smart factories with real-time control and monitoring.

Greater than 45% wall-plug efficiency lowers power draw and cooling needs, reducing operating costs and improving energy performance.

Modular, multi-module construction allows swift swap-out of individual units without halting the full system — cutting downtime and simplifying upkeep.

An optional optical coupler supports flexible beam sharing across multiple stations or heads, maximising utilisation and return on investment.

Engineered for long service life without routine maintenance, reducing total cost of ownership and boosting uptime.

- Precision drilling

- Laser surfacing and cladding

- Soldering and brazing

- Selective heat treatment and hardening

- Processing of highly reflective materials (aluminum, copper, brass)

- Welding of ferrous and non-ferrous metals

Optical and technical characteristics

Technology

Discover new opportunities in the laser industry

We focus on continuous technological development and strive to exceed our customers’ expectations