Products

Key advantages

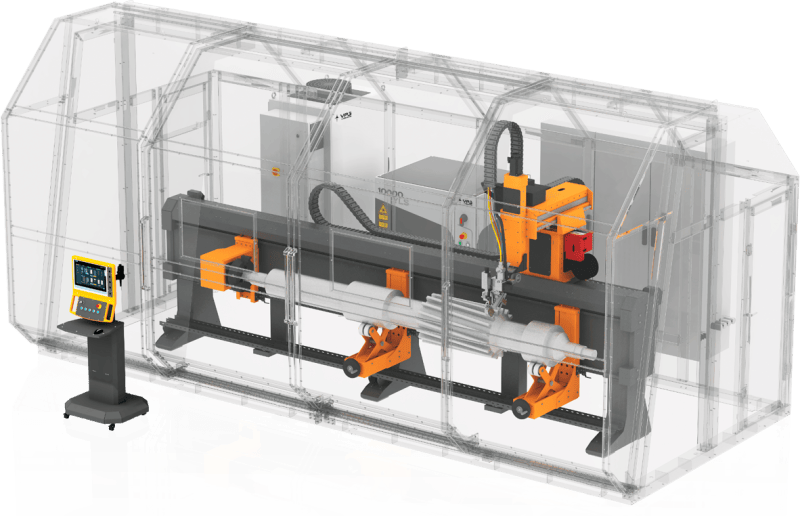

- High deposition rates with minimal scrap for cost-efficient build-up

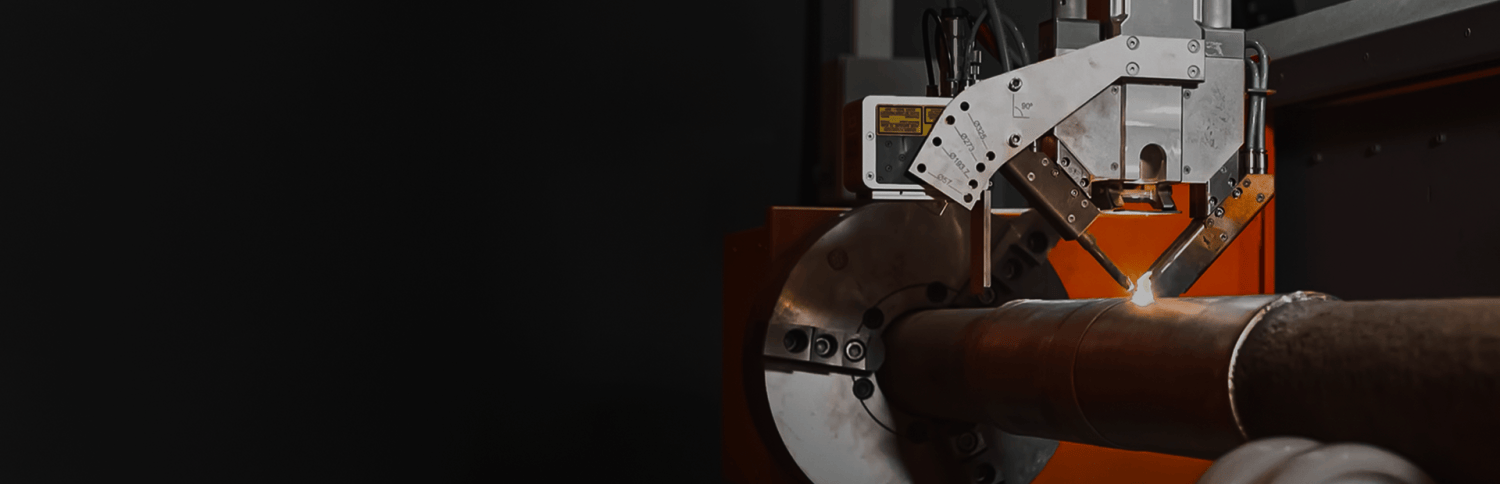

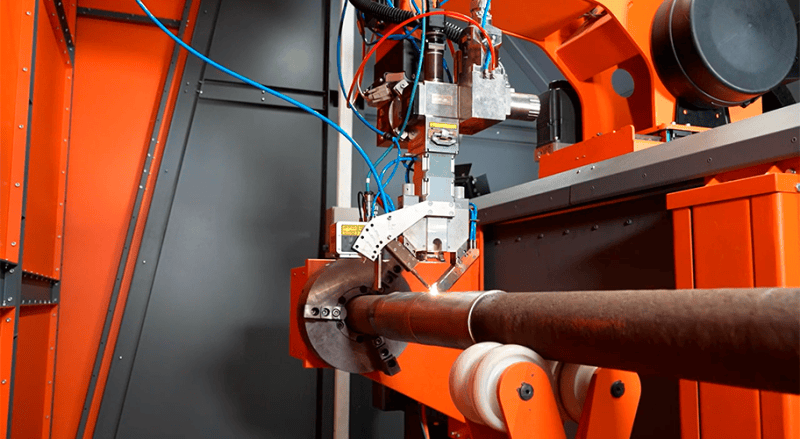

- Consistent bead profile and thickness on large or rotating workpieces

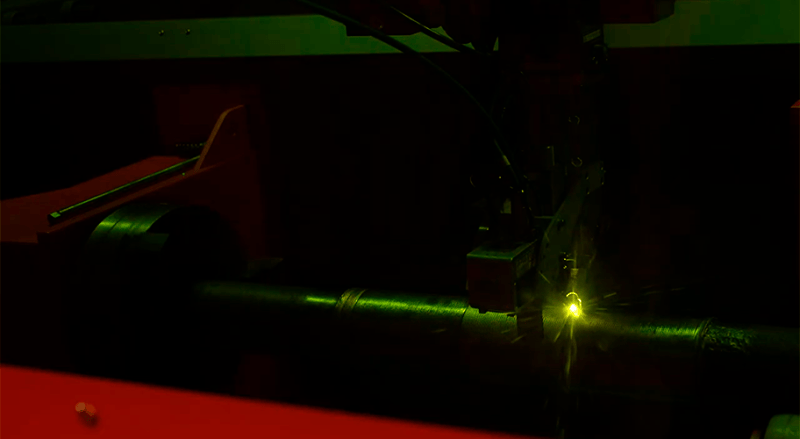

- Lower porosity risk, producing dense, defect-free clad layers

- Stable, controllable parameters suited to structural refurbishment

- Strong metallurgical bonding with adhesion strengths up to ~550 MPa

- Ideal for restoring geometry on large shafts, crankshafts and bearing journals

- Minimal heat input and low residual stresses, preserving part integrity during rebuilds

Discover new opportunities in the laser industry

We focus on continuous technological development and strive to exceed our customers’ expectations