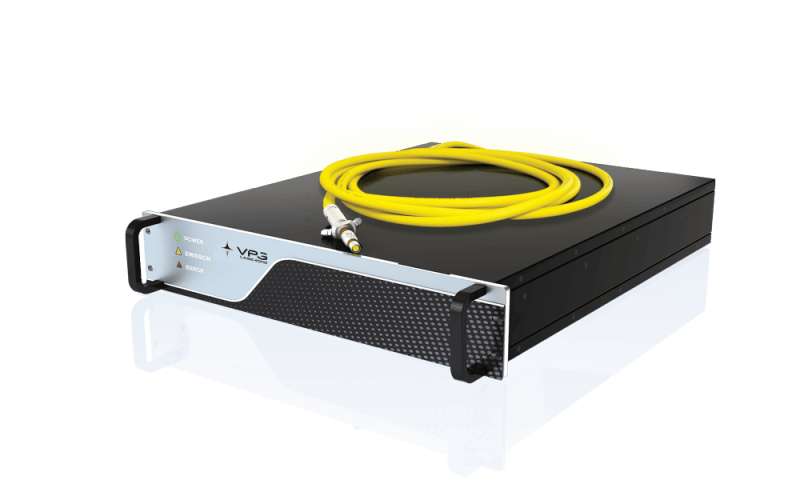

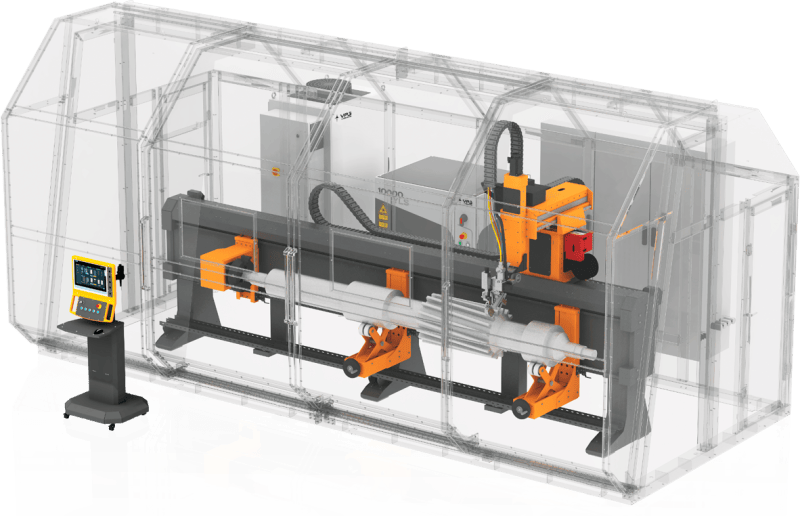

Products

Applications

Key advantages

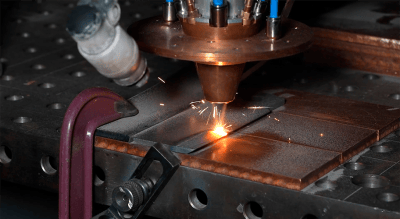

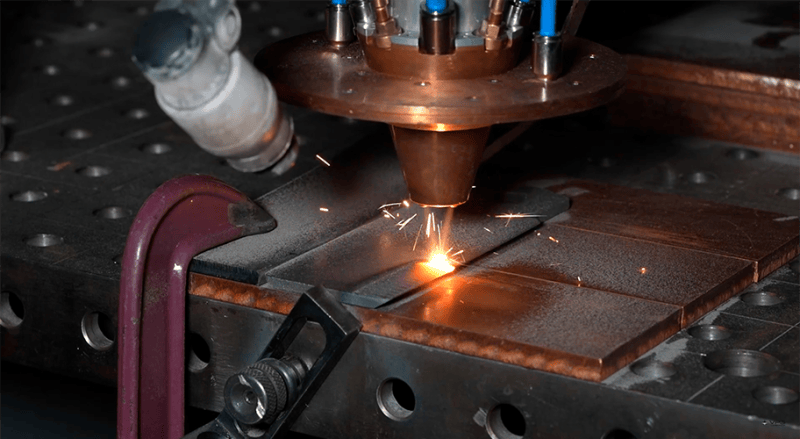

- Supports a wide selection of alloy and carbide powders to create functional, wear-resistant coatings

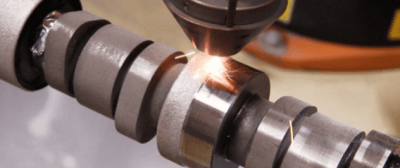

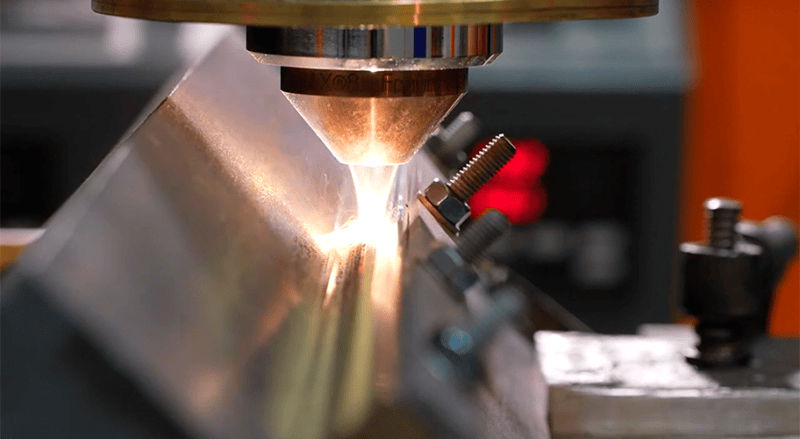

- Offers precise control of layer thickness and surface profile—ideal for fine restorations and engineered overlays

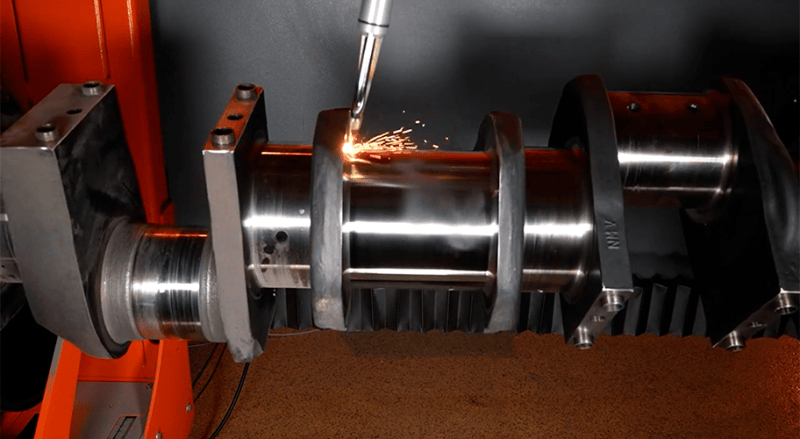

- Produces dense, high-hardness layers (up to ~1000 HV) with excellent wear and corrosion resistance

- Minimises thermal distortion thanks to localised energy input and rapid cooling

- Enables accurate refurbishment of complex or high-value parts such as bearings, rings and blades

- Delivers fine-grained microstructures with strong metallurgical bonding to the substrate

Discover new opportunities in the laser industry

We focus on continuous technological development and strive to exceed our customers’ expectations