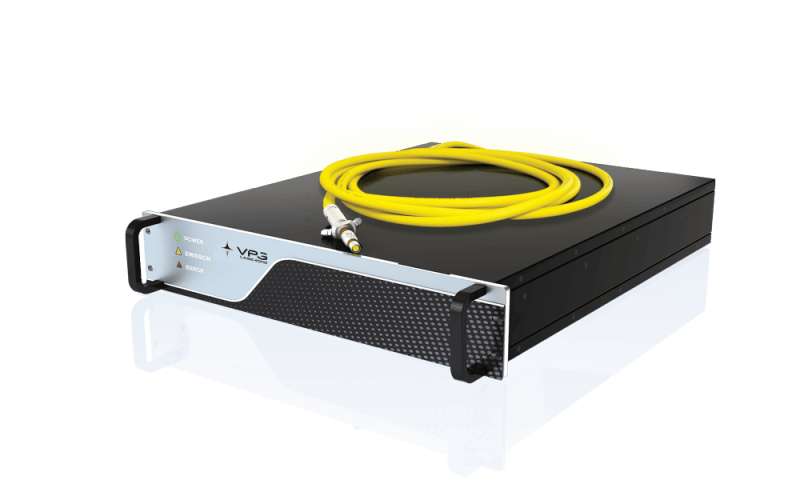

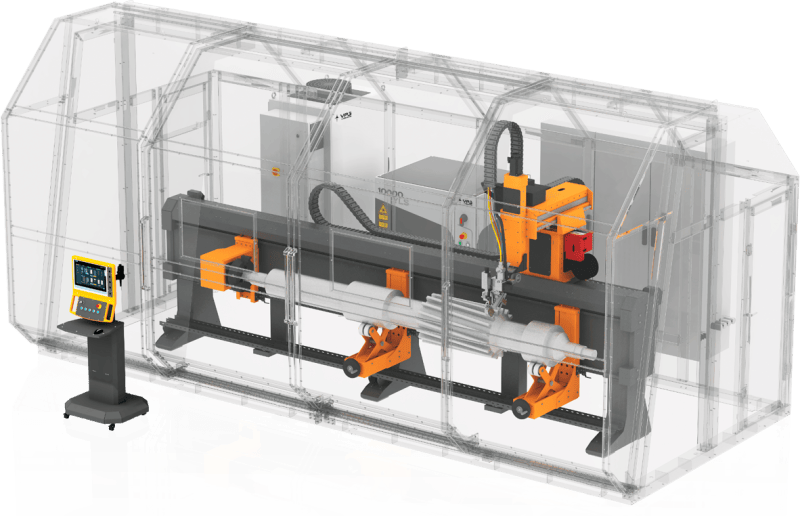

Products

Applications

Key advantages

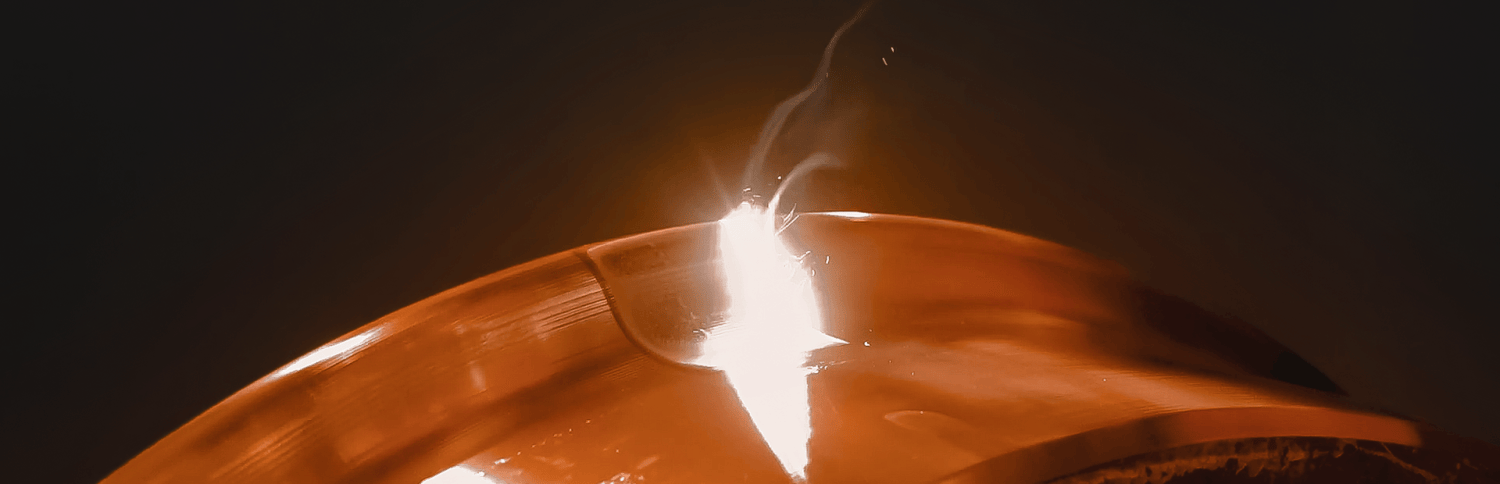

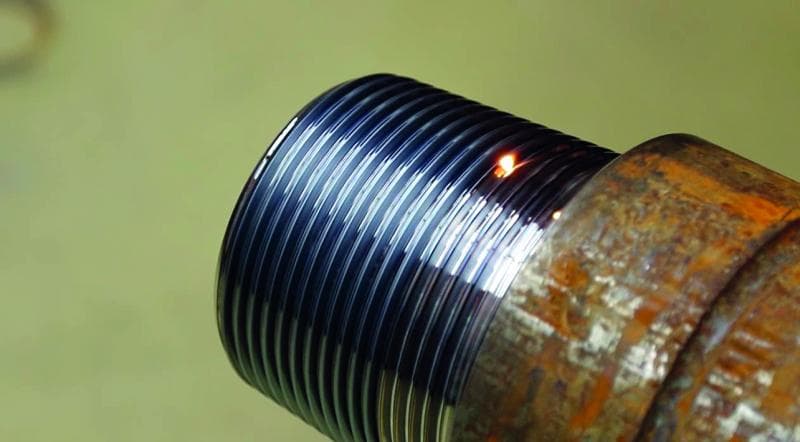

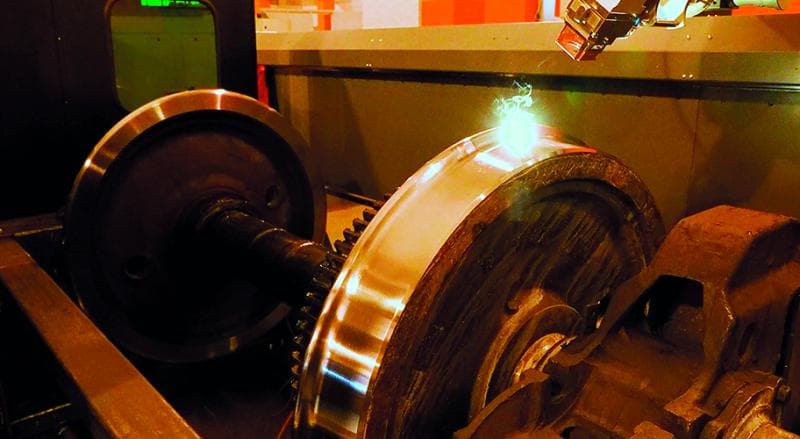

- Up to 4× increase in wear resistance — extending service life and cutting maintenance in industrial use

- Delivers precise, localised hardening — minimising thermal load and outperforming conventional methods

- Ensures minimal distortion and high repeatability for tighter dimensional control and higher productivity

- Eliminates secondary finishing, lowering production costs and shortening turnaround

- Ideal for heavy-duty parts such as shafts, gears, dies and rails — enabling longer service life in demanding conditions

Discover new opportunities in the laser industry

We focus on continuous technological development and strive to exceed our customers’ expectations