Products

Applications

Key advantages

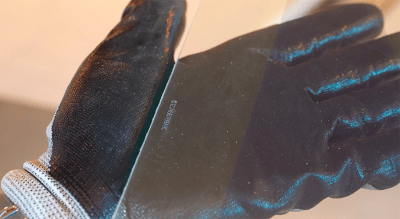

- Marks remain legible after tempering, enabling identification and branding post heat-treatment.

- Supports both surface and sub-surface marking, offering flexibility to match aesthetic or functional needs.

- Non-contact, high-accuracy process produces clean, damage-free marks without affecting transparency or structural integrity.

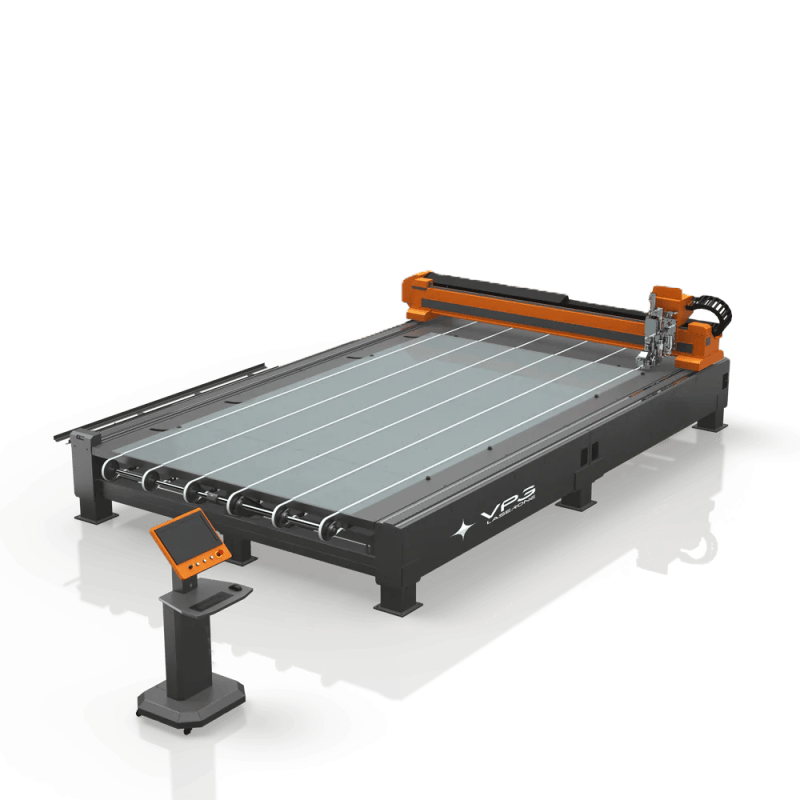

- In-line marking during cutting cycles streamlines production and reduces handling time.

- Durable, wash-proof marks withstand cleaning, weathering and mechanical wear.

- Compatible with jumbo sheets and complex geometries, supporting architectural and industrial-scale workflows.

Discover new opportunities in the laser industry

We focus on continuous technological development and strive to exceed our customers’ expectations